It is a 2-in-1 machine that centrifuges and conveys in continuous flow ALL TYPES OF COFFEE that undergo wet processing, making them dryer and thus streamlining the next drying processes. Versatile, easy to install and to integrate to the existing structure, dispensing adaptive constructions.

With the Centriflux CAFÉS there is an optimization in use of the existing drying facilities, energetic resources and labor. Centriflux speeds up the entire drying process, improving the final quality and commercial value of your coffees.

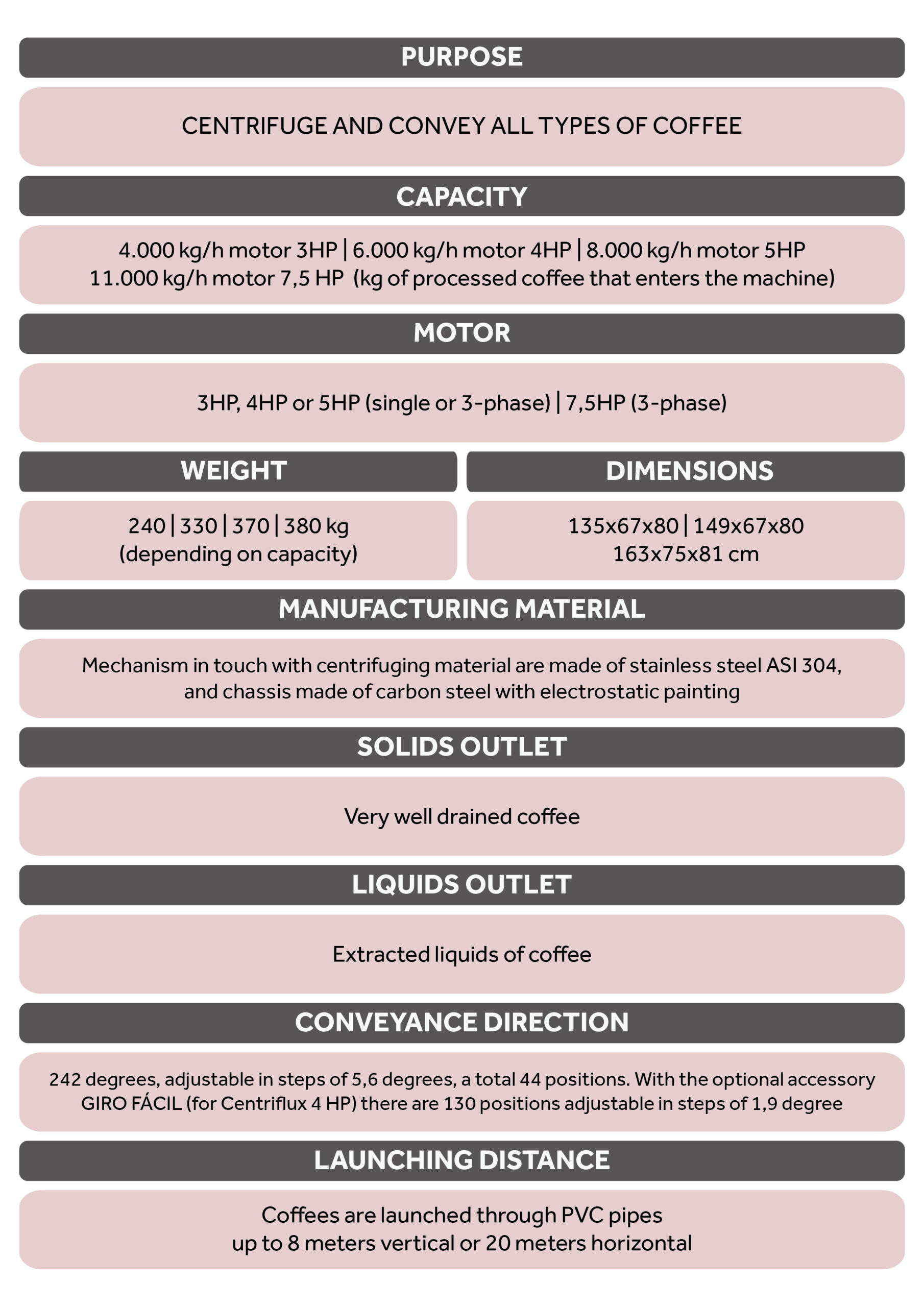

Centrifuges and conveys in continuous flow ALL TYPES OF COFFEE.

4.000/6.000/8.000/11.000 kg/h of wet coffee beans entering the machine.

Extracts instantly the outer liquids of all types of coffee.

No physical harm occur to the coffee beans.

After centrifuged, coffee beans are launched through PVC pipes, with adjustable directions and distances, achieving up to 8 meters vertical or 20 meters horizontal, directly to a hopper, a silo, a cart, a wagon or a truck, with no need of bucket elevator.

In most conditions, coffee may go directly to a dryer just after Centriflux.

Drying time is reduced, saving valuable resources of energy and labor.

Optimizes the efficiency of drying yard, avoiding the need of area expansion. Centrifuged coffee does not wet the ground, the time of stay on yard is shortened, decreasing its exposure to adverse weather conditions and physical harm.

Fungi and bacteria have less time do act negatively.

Durable machine with long intervals within maintenances and easy daily cleaning.

The practical results are a confluence of positive aspects, since improvements of logistics and processes, up to a better end quality of coffee.

Extracts excess liquid mucilage. Makes handling easier, does not wet the ground and reduces the risk of unwanted fermentation. Results in excellent quality coffees.

Coffee beans get very well drained and easy to be taken directly to a dryer. Does not wet the drying yard, easy to handle and speeds up the drying process and improves final aspect.

Completely removes superficial water, fruit getting in same condition as it was harvested.

Fermentation process is sharply interrupted, fermented mash is well drained, keeping intact the coffee skin, making drying easy and without risk of continued fermentation.

Gets very well drained, rehydration is avoided, risk of undesired mold and fermentation is lowered. lt does not wet the ground, saving drying time, hence coffee can be taken directly to a dryer.

Beyond centrifugation, Centriflux CAFÉS performs the conveyance of centrifuged coffee through PVC pipes, with no need of bucked elevators.

* Launching the beans in free flight over a yard will separate coffee and impurities by density: dense fall further, light fall nearer.

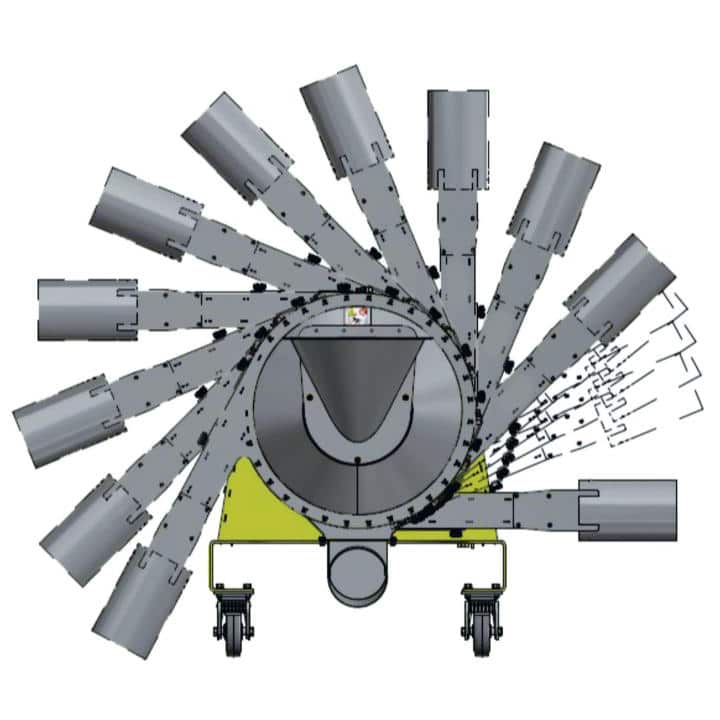

With the Standard Giro, the direction of conveyance is adjustable in 44 positions, in steps of 5,6 degrees, to achieve distances up to 8 m vertical or 20 m horizontal, depending on capacity. The 4 HP Centriflux, with 6.000 kg/h of capacity, equipped with GIRO FÁCIL offers 130 positions, adjustable in 1,9 degree steps.

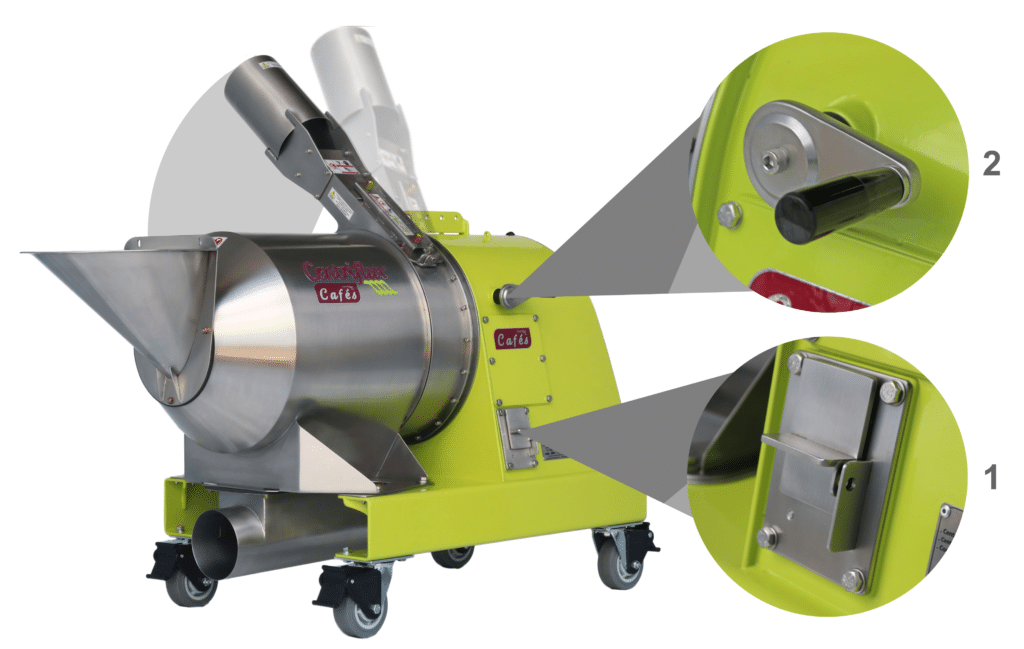

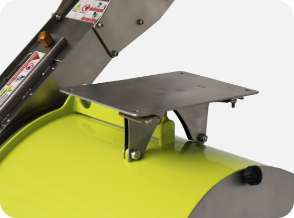

The 4 HP Centriflux CAFÉS with capacity of 6.000 kg/h is available in two versions: with STANDARD GIRO or with GIRO FÁCIL, one may change the launching angle of centrifuged coffee very quickly and with less effort, without need of tools or fasteners. Just unlock the safety lock (1), move the crank handle (2) until the launcher finds the new direction, lock it and it’s done!

The range of applications in a wet and dry mill of coffee are increased with the optional GIRO FÁCIL. It is quite easy to move your Centriflux from one place to another, adjust a new launching direction, and feed a new target, like a wagon, a truck, a silo, a hopper, launch it over an yard, load a dryer or even move dry beans in bulk.

The Centriflux Cafés equipped with Standard Giro requires tools to deal with fasteners and change the launching angle. Nevertheless, this is still a good option in case you intend to maintain the machine in one permanent position and doing a specific task. But, in case you started with Standard Giro, further you may upgrade your machine to the GIRO FÁCIL (just for 4 HP Centriflux, 6.000 kg/h capacity).

Enlarged hopper size, for a wider reception of coffee beans.

An alternative safety item, only for clean parchment coffee.

Install an on board electrical control for improved mobility of the machine.

VERSATILE, HIGH PERFORMANCE, ECO-EFFICIENT, ROBUST, COMPACT DESIGN, EASY USE

*Granted patents and pending patents: INPI & PATENT COOPERATION TREATY